Live|Apri 23rd, 2025 14:30-15:30

2024 SUSTAINABILITY REPORT RELEASE

2024 BOE Sustainability Report

BOE has always adhered to the belief of "Coexisting with Nature, Creating a Better World Together," dedicating itself to safeguarding Earth's resources through green initiatives, educational philanthropy, inclusive healthcare, and cultural empowerment—working hand in hand with you for a sustainable future.

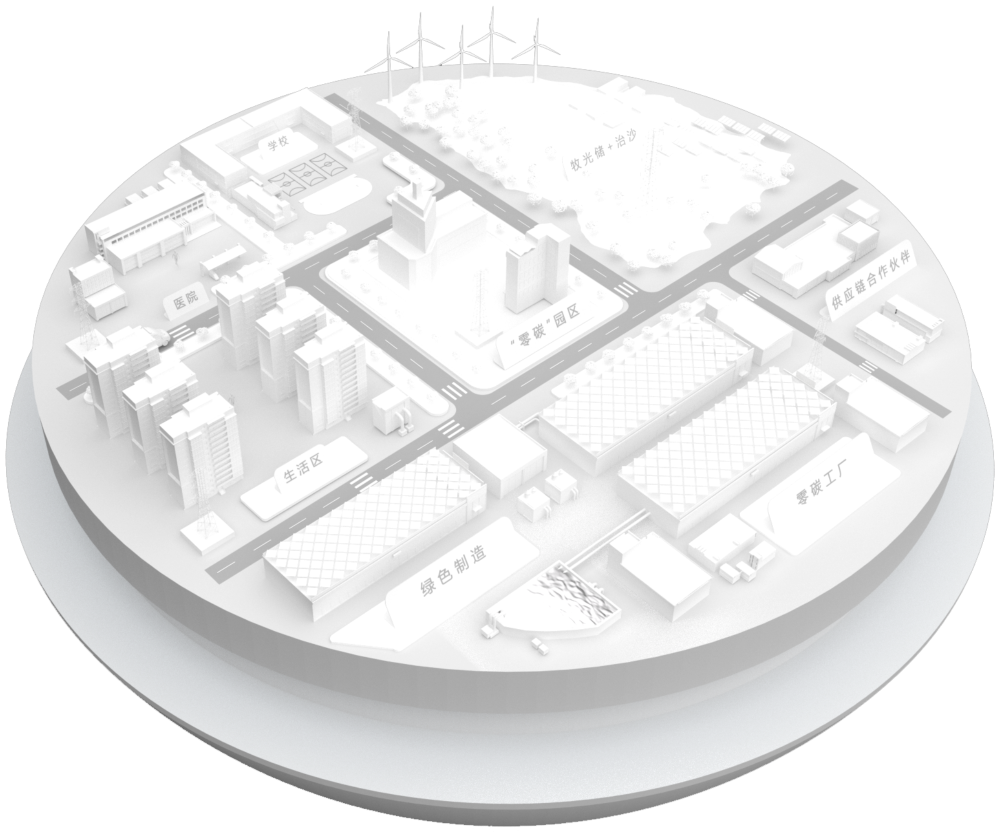

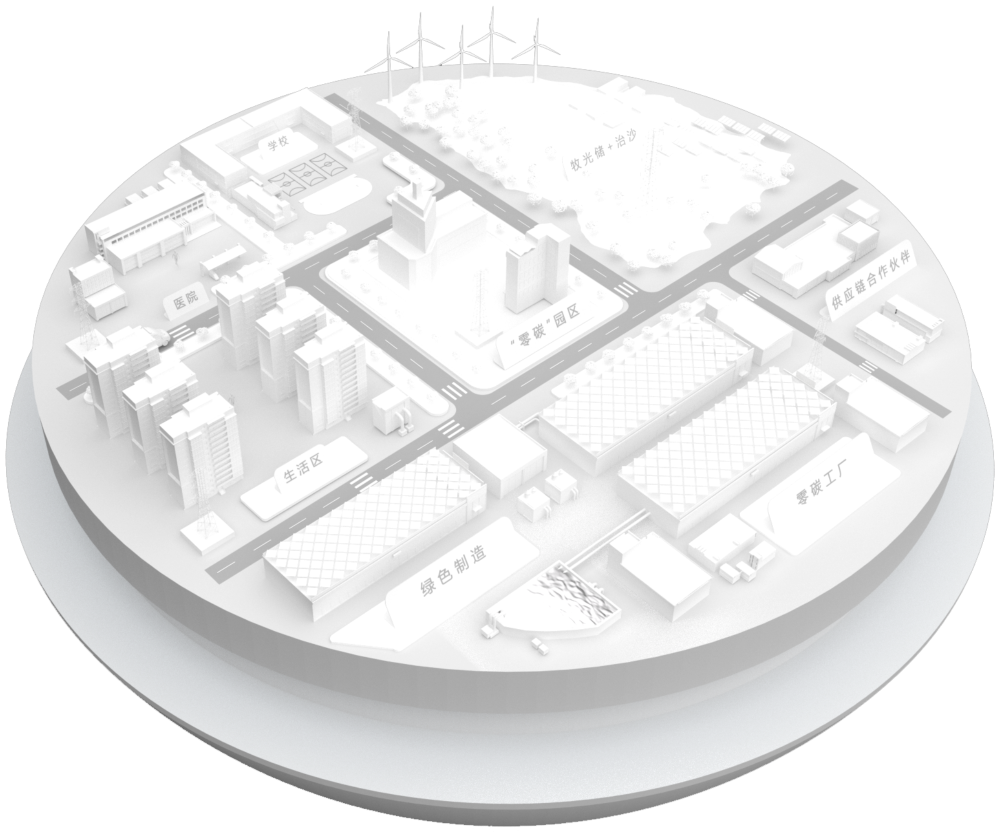

MR SIMULATION SANDBOX DISPLAY OF ONE

Zero-Carbon Factory

• BOE’s Mianyang 6th Gen Flexible AMOLED Production Line became the industry’s first “Zero-carbon Factory”

• Through its innovative model of "Green Electricity Coverage + Carbon Footprint Management + Technological Decarbonization", it achieved "Carbon Neutrality" in production processes

Supply Chain Partnerships

·Committed to low-carbon, non-toxic, and resource-efficient practices

·Full lifecycle product management across:Green Certification | Eco-Design | Sustainable Production | Green Logistics | Circular Economy

·26,519 tons of CO₂ reduced in 2024 through 20+ key projects

Sonid Right Banner: Integrated Photovoltaic Storage + Desertification Control

200 MW photovoltaic capacity deployed

Advanced energy storage system with 42.5 MW/85 MWh charge/discharge capacity

Pioneering "PV + Energy Storage + Desert Restoration + Livestock Farming" holistic solution

Green Smart Low-Carbon Industrial Park

Established an AI-powered Energy Management Platform to enable multi-dimensional coordination of energy "Generation-Grid-Load-Storage-Carbon" systems

Achieved 52% energy efficiency improvement and 37% carbon reduction

Green Manufacturing

• 18 factories certified as "National-level Green Factory"

• The only National-level "Zero Waste Factory" in the display industry

• 1 plant as "Lighthouse Factory" (World Economic Forum benchmark)

• 2 factories certified as "Zero-Carbon Factories"

• BOE has also actively responded to international initiatives such as the Science Based Targets initiative (SBTi) and CDP, with 7 of its factories joining the SBTi.

UNESCO Partnership

BOE partners with UNESCO as the first Chinese technology company to support the United Nations "Decade of Science", committed to advancing global scientific literacy and technology outreach

Free Medical Clinics

Conducted 1,781 free medical clinics in 2023,Benefited over 344,000 individuals

Green Initiatives

Accumulated participation: 1,320,000 person-times,Reduced carbon emissions by 8,453 tons of CO₂

Energy Efficiency Upgrade

Revamped the MB regeneration heat source at Hefei’s 10.5th Gen TFT-LCD production line to enhance thermal recovery chiller efficiency:

• Annual electricity savings: 323,000 kWh per year

• Annual energy savings: 39.70 tons of standard coal

• Annual carbon reduction: 173.32 tons of CO₂ equivalent (electricity emission factor 0.5366)

Reclaimed Water Utilization

Upgraded water-saving systems and recycling rates at Beijing’s 8.5th Gen production line

Achieved 100% reclaimed water usage for production, with daily consumption exceeding 20,000 tons

Annual savings of 3.3 million tons of reclaimed water, equivalent to the annual water consumption of 7,000 residents

"Light Up Growth Path" & "The Palace Museum Cultural Courses"

Since 2014, BOE’s "Light Up Growth Path" CSR educational initiative:Established 126 smart classrooms in remote areas in 8 provinces, benefiting over 63,500 teachers and students

Collaborated with the Palace Museum to deliver 400+ sessions of cultural heritage courses

Perovskite Photovoltaic Module

• BOE SOLAR’s self-developed 300×300mm large-area perovskite solar cell achieves 20% conversion efficiency breakthrough

• Breaks through light intensity threshold limits, enabling full-range light sensing across PV modules

Integrated Utilization of Cold & Heat Source

Establishes a cross-system heat exchange network through advanced thermal energy coupling technologies (e.g., waste heat recovery), creating an internal thermal energy circulation loop within the plant, thereby minimizing the system’s overall energy consumption.

Free Cooling

Utilizes idle low-temperature cooling towers during winter to generate medium-temperature chilled water through free-cooling plate heat exchangers, thereby reducing chiller power consumption.

By-Production Water Recycling

Conducts a comprehensive analysis of water intake and discharge points throughout the plant, followed by additional treatment of effluent for reuse applications, ultimately decreasing the facility's total municipal water demand.

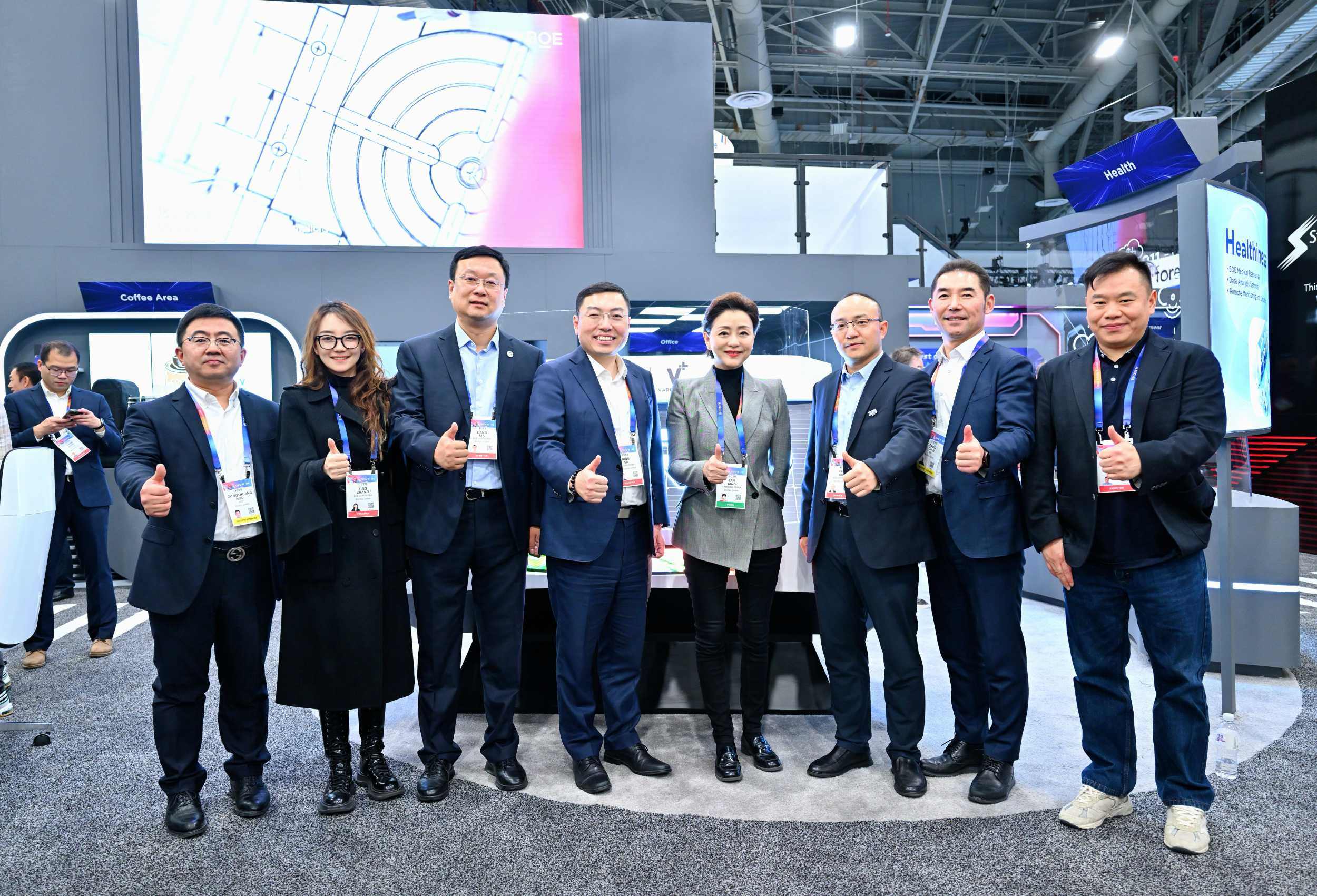

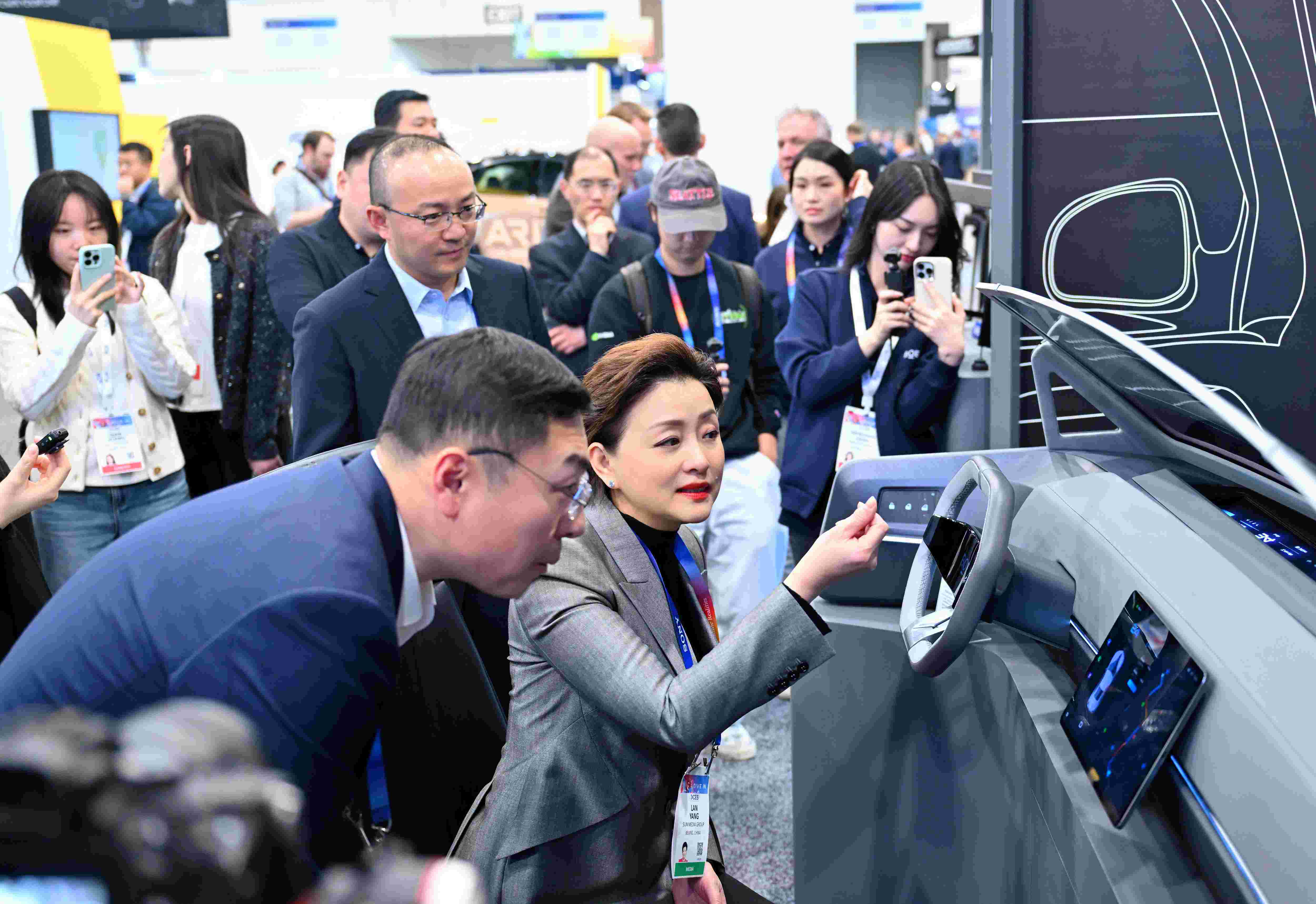

ON-SITE PHOTO

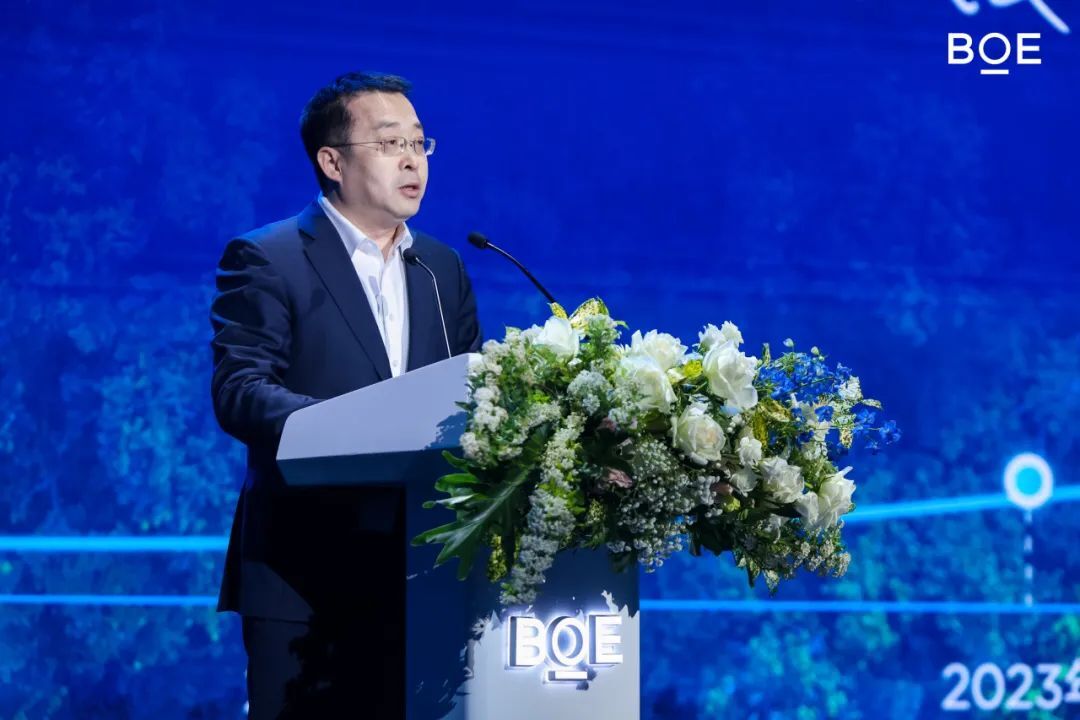

2024 SUSTAINABILITY REPORT RELEASE

BOE SUSTAINABILITY LOGO

BOE SUSTAINABILITY LOGO

Value : Built to Sustain

Implication: Open Next Earth

- Open:Fostering a global ecosystem of shared dedication

- Next:Shaping technology’s value through the lens of tomorrow

- Earth:Defining a new paradigm for technology-ecology symbiosis

2024 SUSTAINABILITY REPORT RELEASE

2024 BOE Sustainability Report

BOE has always adhered to the belief of "Coexisting with Nature, Creating a Better World Together," dedicating itself to safeguarding Earth's resources through green initiatives, educational philanthropy, inclusive healthcare, and cultural empowerment—working hand in hand with you for a sustainable future.

MR SIMULATION SANDBOX DISPLAY OF ONE

Zero-Carbon Factory

• BOE’s Mianyang 6th Gen Flexible AMOLED Production Line became the industry’s first “Zero-carbon Factory”

• Through its innovative model of "Green Electricity Coverage + Carbon Footprint Management + Technological Decarbonization", it achieved "Carbon Neutrality" in production processes

Supply Chain Partnerships

·Committed to low-carbon, non-toxic, and resource-efficient practices

·Full lifecycle product management across:Green Certification | Eco-Design | Sustainable Production | Green Logistics | Circular Economy

·26,519 tons of CO₂ reduced in 2024 through 20+ key projects

Sonid Right Banner: Integrated Photovoltaic Storage + Desertification Control

200 MW photovoltaic capacity deployed

Advanced energy storage system with 42.5 MW/85 MWh charge/discharge capacity

Pioneering "PV + Energy Storage + Desert Restoration + Livestock Farming" holistic solution

Green Smart Low-Carbon Industrial Park

Established an AI-powered Energy Management Platform to enable multi-dimensional coordination of energy "Generation-Grid-Load-Storage-Carbon" systems

Achieved 52% energy efficiency improvement and 37% carbon reduction

Green Manufacturing

• 18 factories certified as "National-level Green Factory"

• The only National-level "Zero Waste Factory" in the display industry

• 1 plant as "Lighthouse Factory" (World Economic Forum benchmark)

• 2 factories certified as "Zero-Carbon Factories"

• BOE has also actively responded to international initiatives such as the Science Based Targets initiative (SBTi) and CDP, with 7 of its factories joining the SBTi.

UNESCO Partnership

BOE partners with UNESCO as the first Chinese technology company to support the United Nations "Decade of Science", committed to advancing global scientific literacy and technology outreach

Free Medical Clinics

Conducted 1,781 free medical clinics in 2023,Benefited over 344,000 individuals

Green Initiatives

Accumulated participation: 1,320,000 person-times,Reduced carbon emissions by 8,453 tons of CO₂

Energy Efficiency Upgrade

Revamped the MB regeneration heat source at Hefei’s 10.5th Gen TFT-LCD production line to enhance thermal recovery chiller efficiency:

• Annual electricity savings: 323,000 kWh per year

• Annual energy savings: 39.70 tons of standard coal

• Annual carbon reduction: 173.32 tons of CO₂ equivalent (electricity emission factor 0.5366)

Reclaimed Water Utilization

Upgraded water-saving systems and recycling rates at Beijing’s 8.5th Gen production line

Achieved 100% reclaimed water usage for production, with daily consumption exceeding 20,000 tons

Annual savings of 3.3 million tons of reclaimed water, equivalent to the annual water consumption of 7,000 residents

"Light Up Growth Path" & "The Palace Museum Cultural Courses"

Since 2014, BOE’s "Light Up Growth Path" CSR educational initiative:Established 126 smart classrooms in remote areas in 8 provinces, benefiting over 63,500 teachers and students

Collaborated with the Palace Museum to deliver 400+ sessions of cultural heritage courses

Perovskite Photovoltaic Module

• BOE SOLAR’s self-developed 300×300mm large-area perovskite solar cell achieves 20% conversion efficiency breakthrough

• Breaks through light intensity threshold limits, enabling full-range light sensing across PV modules

Integrated Utilization of Cold & Heat Source

Establishes a cross-system heat exchange network through advanced thermal energy coupling technologies (e.g., waste heat recovery), creating an internal thermal energy circulation loop within the plant, thereby minimizing the system’s overall energy consumption.

Free Cooling

Utilizes idle low-temperature cooling towers during winter to generate medium-temperature chilled water through free-cooling plate heat exchangers, thereby reducing chiller power consumption.

By-Production Water Recycling

Conducts a comprehensive analysis of water intake and discharge points throughout the plant, followed by additional treatment of effluent for reuse applications, ultimately decreasing the facility's total municipal water demand.

GREEN PRODUCTS

23.8" Green MNT

23.8" Green MNT

23.8" Green MNT

ON-SITE PHOTO & VIDEO

ON-SITE PHOTO

OUR MISSION

BOE at CES2025

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Donec odio. Quisque volutpat mattis eros. Nullam malesuada erat ut turpis. Suspendisse urna nibh, viverra non, semper suscipit, posuere a, pede. Donec nec justo eget felis facilisis fermentum.

OUR MISSION

BOE at CES2025

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Donec odio. Quisque volutpat mattis eros. Nullam malesuada erat ut turpis. Suspendisse urna nibh, viverra non, semper suscipit, posuere a, pede. Donec nec justo eget felis facilisis fermentum.